- Home

- Products

-

- BT30 BT40 ER Collet Chuck

- ST GER High Speed Collet Chcuk

- ISO ERMS High Speed Collet Chuck

- NBT30-GER Higher Speed Collet Chuck without Keyway

- HSK ERMS Collet Chuck

- SK(DIN69871、JT、DAT)GER Collet Chuck

- BT30/40-GER Collet Chuck

- ISO GER High Speed Collet Chuck without Keyway

- HSK GER High speed collet chuck

- ST GER High Speed Collet Chcuk

-

-

- SK(DIN69871、JT、DAT或DV) ER Collet Chuck with M type Nut Share to: SK(DIN69871、JT、DAT或DV) ER Collet Chuck with M type Nut

- SK(DIN69871、JT、DAT/DV) ER Collet Chuck with M type Nut

- SK(DIN69871、JT、DAT或DV) ER Collet Chuck

- NBT30-ER High Speed Collet Chuck Without Keyway

- SK(DIN69871、JT、DAT/DV) ER Collet Chuck with M type Nut

- ISO ER Collet Chuck

- BT50 ER Collet Chuck

- BT ER Collet Chuck with M type Nut

- CBBT ER Collet Chuck

- CBBT GER High Speed Collet Chuck

- ER COLLET DIN6499B

-

-

-

-

-

- BT C Straight Power Milling Chuck

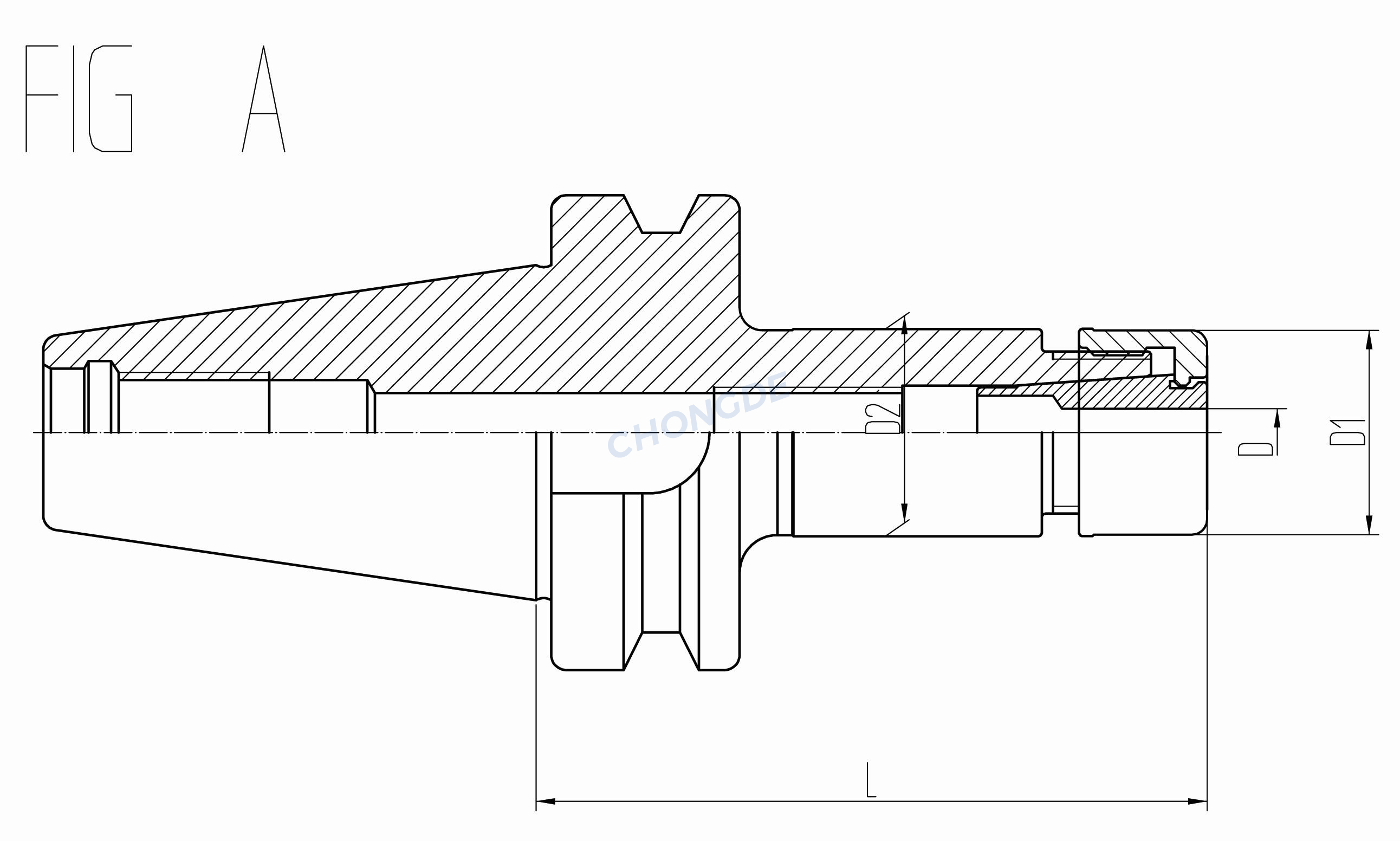

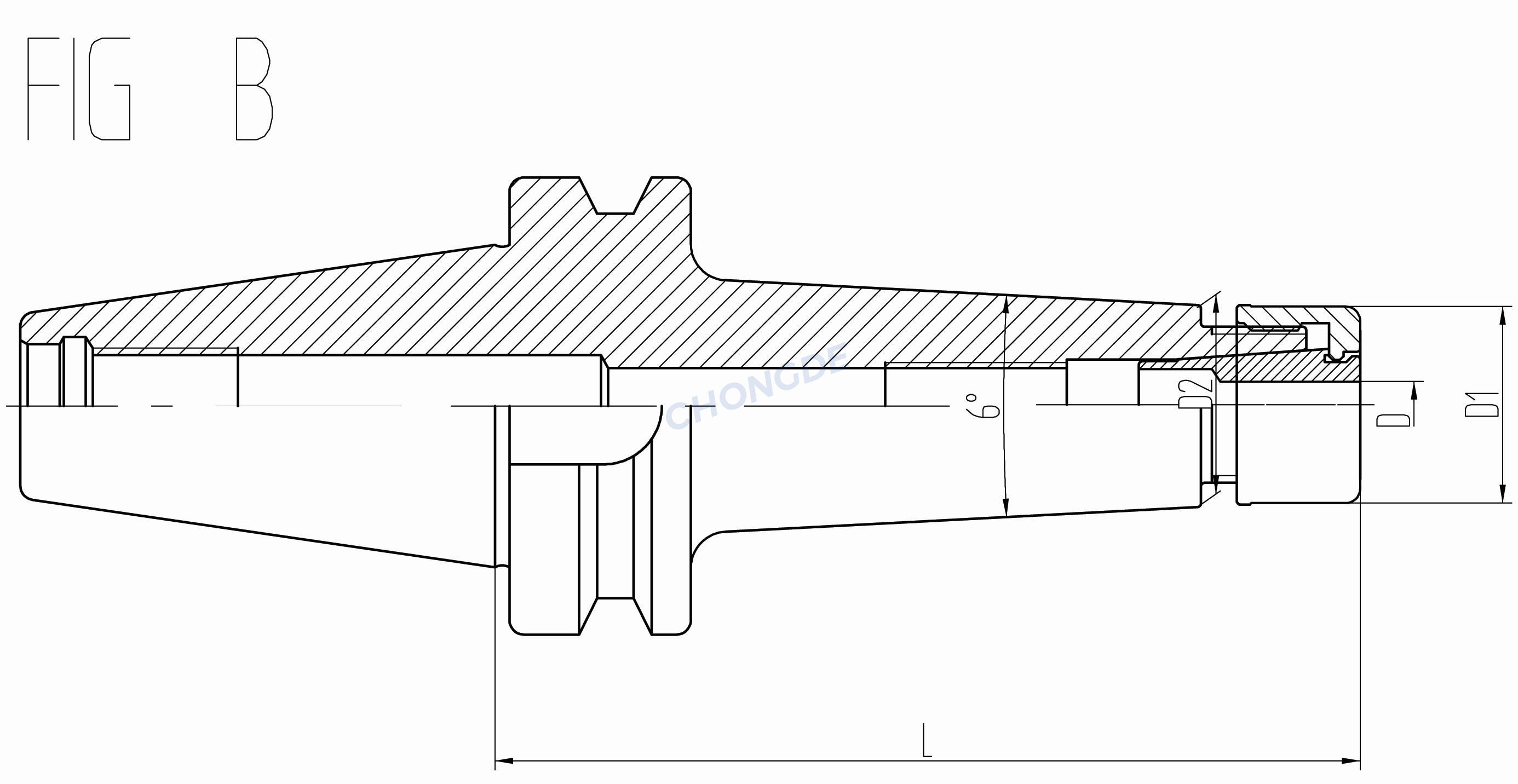

- SK (DIN69871) C Straight Power Milling Chuck

- HSK C Straight Power Milling Chuck

- CAT C Straight Power Milling Chuck

- NT C Straight Power Milling Chuck

- MTA/MTB Moser Taper Shank Milling Chuck

- R8 C Straight Power Milling Chuck

- C Type Spanner

- Milling Chuck Set

- C Straight Collet

- K Straight Collet

- Straight Shank Morse Taper Sleeve

-

-

-

-

- HSK63A APU DRILL CHUCK

- EOC (OZ) Collet Chuck

- Drill Chuck System

- Live Centers

- Drill Chuck Arbors

- Sleeve Series

- Milling Machine Arbor Series

- Boring Head Series

- VDI Tool Holder Series

- Hydraulic Soft Jaws Series

- Precision Tool Vises

- Touch Point Senso

- CNC Accessories

- Electromagnetic Heater

- Indexable CNC Tool Series

- Anti-vibration Tungsten Steel CNC Milling Shank, Bore Arbor

- Disposable Rapid Drilling Tools

- Rubber Collets

- Carbide Lined Guide Bushing & Collets

-

-

-

-

- New Products

-

- HSK SSD Shrink Fit CNC Chuck

- BT SSD Shrink Fit CNC Chuck

- SK SSD Shrink Fit CNC Chuck

- BT SSD Light Type Shrink Fit CNC Chuck

- Shrink Fit CNC Chuck with End-effluent

- BT/HSK/CAT SSF Replaceable Shrink Fit Chuck

- HSK63A SSD Light Type Shrink Fit CNC Chuck

- SSD Shrink Fit Extension Bar

- Replaceable Joint Shrink Fit Chuck

- SSF Hot Retraction Rod

- Switchable SSF Type Hot Retraction Rod

-

-

-

- News

- About ChongDe

- E-Catalogs

- Contact Us

JunTai Road, West Economic Development Zone